UNINET® Blog

| TRANSFER NEWS

How to Choose the Perfect Printer for Your New T-Shirt Business

By Joe Dovi

Starting a T-shirt business is exciting… right up until you realize there are five popular ways to print shirts and everyone online swears theirs is “the best.” The truth is: the “perfect” printer depends on what you want to sell, who you’re selling to, how much you want to learn, and how much time you want to spend maintaining equipment.

This guide breaks down the most common decoration methods—White Toner, DTF, Sublimation, HTV, and Screen Printing—so you can pick the best match for your goals. And if you want the most flexible, beginner-friendly option that can grow with you, you’ll see why white toner transfer printers are often the smartest first investment.

1. Ask the Questions That Actually Matter

Before comparing printers, get clear on these:

What will you print most?

* Full-color logos? Small left-chest prints? Big back designs? Names & numbers?

What materials will you decorate?

* Just cotton tees?

* Polyester performance shirts?

* Or do you want to sell more than shirts (tumblers, wood signs, decals, metal plates, etc.)?

How many orders per day?

* A few custom orders daily are different from 100+ shirts per week.

How hands-on do you want to be?

* Others are closer to “print → press → done.”

* Some methods require daily upkeep and tuning.

2. The Big 5 Printing Methods (Pros, Cons, Best Use)

A) White Toner Printing (The “Most Versatile Starter” Option)

How it works: A specialized laser/toner printer prints your design with dry white toner onto a transfer sheet. Then you heat-press it onto fabric or other substrates.

Best for: Startups that want flexibility, simple workflow, and the ability to sell beyond apparel.

Why do people love it:

- * No daily ink maintenance (toner doesn’t dry out like ink)

- * Extremely versatile (works on light and dark items)

- * Easy to learn (print + press workflow, minimal tuning)

- * Can be used as a regular printer (great for office use, order forms, labels, etc.)

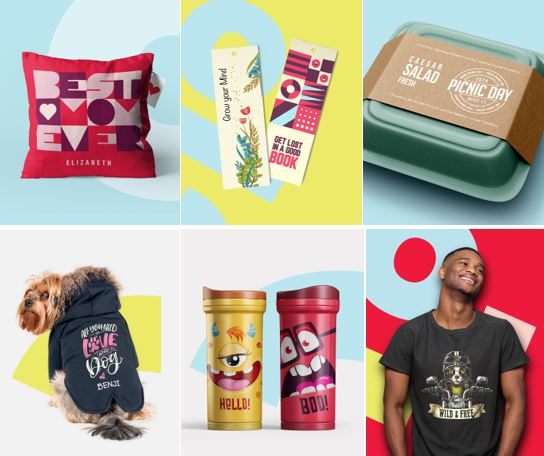

- * Decorates tons of substrates—not just shirts:

- Metal, glass, acrylic, ceramic, wood, and more.

- * Great for small runs, custom orders, and product expansion.

- * Can be upgraded with toner cartridge upgrade kits (clear, metallics, sublimation, fluorescent colors, and more)

Considerations:

- Transfer feel can vary based on papers/adhesives and pressing technique (and artwork preparation).

- Best results come from using the right transfer paper for the right material.

If you want one printing system that can launch a T-shirt business and quickly expand into profitable “hard goods,” white toner printing is hard to beat. Even when your business scales and you need to move to other production methods, White Toner is an excellent backup when your primary printing system goes down, and the incredible versatility means it will be one of the most used printers in your print shop.

If you have room for just one printer, most users choose a white toner printer every time!

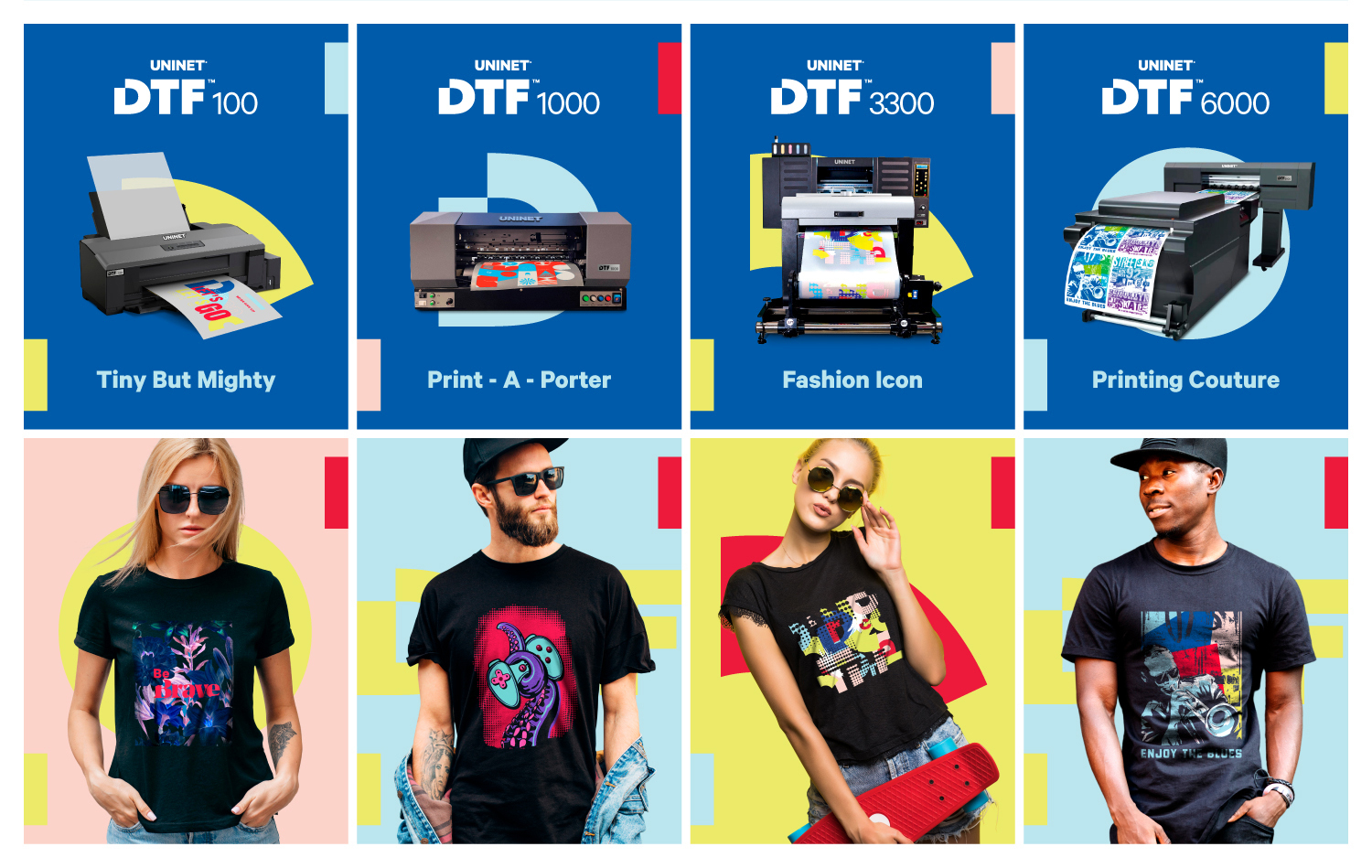

B) DTF (Direct-to-Film) Printing (The “Great for Apparel Volume” Option)

How it works: A printer lays down ink on film, adds powder adhesive, cures it, then you press it onto garments.

Best for: Businesses focused heavily on apparel with lots of full-color designs.

Pros:

- * Very popular for vibrant apparel prints

- * Works on many fabrics (cotton, blends, etc.)

- * Excellent for complex designs and gradients

- * Low cost per print as compared to other methods

Cons:

- * Maintenance can be real (DTF ink systems need regular attention)

- * Powder + curing adds equipment and steps (and health concerns)

- * More “production process” than “simple printer setup”

DTF printing is fantastic when apparel is the main product and you’re ready for a more hands-on production routine. It’s best suited to make transfers in bulk (gang sheets or rolls) but it is somewhat tedious when you are using it to make garments yourself because of all the labor involved with cutting up the designs on a large table.

C) Sublimation (The “Best for Polyester + Hard Goods… with a Catch”)

How it works: Sublimation ink turns into gas under heat and bonds into polyester fibers or poly-coated items.

Best for: Polyester garments and poly-coated hard goods (mugs, metal panels, etc.).

Pros:

- * Super durable prints (it becomes part of the material)

- * Great for bright, clean results on the right substrates.

- * Great for many gift items if they’re polyester-coated.

Cons:

- * Doesn’t work on cotton (needs 100% polyester)

- * Works best on light-colored substrates.

- * Hard goods must be poly-coated, not raw materials.

Sublimation is amazing if your niche is polyester and coated blanks, but it’s not the most flexible all-around option for a typical “cotton tee + anything else” startup.

D) HTV (Heat Transfer Vinyl) (The “Cheap to Start, Manual to Scale” Option)

How it works: You cut vinyl with a cutter, weed it by hand, and heat-press it onto garments.

Best for: Names/numbers, simple logos, single-color or layered designs.

Pros:

- * Low startup cost.

- * Great for short runs and personalization (team shirts, names)

Cons:

- * Weeding is time-consuming (labor becomes the bottleneck)

- * Multi-color designs get tedious fast. Best used for monochromatic designs.

- * More “craft production” than scalable printing.

HTV printing is a solid entry point, but many businesses outgrow it quickly once orders increase.

E) Screen Printing (The “Best for Big Bulk Orders” Option)

How it works: You create screens and press ink through them onto shirts. Best when doing many of the same design.

Best for: Large runs—think 50, 100, 500 shirts of one design.

Pros:

- * Lowest cost per shirt at high volume.

- * Classic look and feel.

- * Extremely scalable with the right setup.

Cons:

- * Setup time and skill.

- * Space, chemicals, screens, cleanup.

- * Not ideal for lots of one-off designs.

If you already have bulk clients lined up, screen printing can be king. If you’re starting with custom orders, it’s usually not the easiest “first machine.”

3. So... What's the Best Choice For a New T-Shirt Business?

If your goal is to start selling quickly, keep the workflow simple, and avoid getting trapped in constant equipment upkeep, white toner printing is often the best all-around solution, especially for startups.

Why the blog’s recommendation is White Toner Printing…

White toner transfer printers shine because they check the boxes most new businesses need:

- * No maintenance (no clogged heads, no daily ink babysitting)

- * Extremely versatile

- * Easy to use

- * Can function as a regular printer

- * Decorates way more than shirts

- Expand into metal, glass, acrylic, ceramic, wood, and more.

- Perfect for short runs, custom orders, and high-margin product variety.

In other words: White toner printing doesn’t just help you start a T-shirt business—it helps you build a customization business.

4. A Simple Starter Strategy (That Makes Money Fast)

If you’re starting from scratch, here’s a practical path:

- Start with white toner printing for easy custom apparel + product expansion.

- Add HTV printing for quick names/numbers (optional).

- If apparel volume explodes, consider adding DTF printing later for throughput.

- If you land big bulk clients, explore screen printing.

- If you niche into polyester + coated blanks, add sublimation (IColor white toner printers can also be upgraded with sublimation toners!)

Final Thoughts

The “perfect printer” isn’t the one with the most hype—it’s the one that matches your business model today, while giving you room to grow tomorrow.

If you want a setup that’s:

- * Beginner-friendly

- * Low maintenance

- * Capable of decorating both shirts and profitable hard goods…

White Toner Printing is the best recommendation for most new T-shirt businesses.