UNINET® Blog

| FEATURE NEWS, TRANSFER NEWS

The Best DTF Printer Alternative - White Toner Printers!

by Joe Dovi

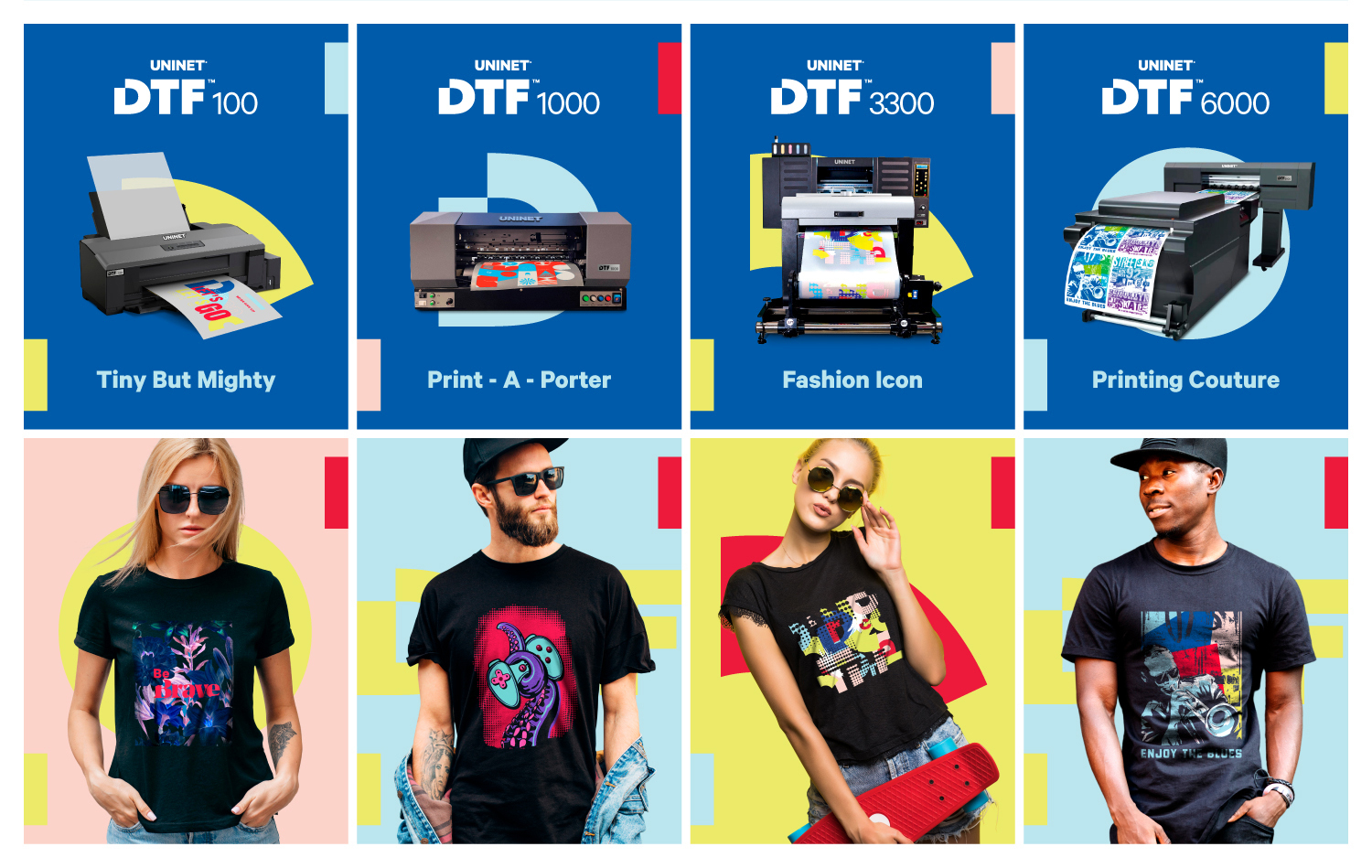

While traditional DTF printers are the hottest trend in the short-run garment decoration space, White Toner Printers (sometimes called WT printers) can be considered a form of DTF and are now being called the best “DTF Alternative” for startups and small businesses.

In fact, recently you may have noticed that the White toner category of printers has been referred to as “White Toner DTF,” “Powderless DTF Printers,” or “No Powder DTF Printers.” In short, the term “DTF” stands for Direct to Film, so it’s true that these printers are printing “direct to film” as well. You might classify these printers as a form of DTF without all the fuss of maintaining an ink delivery system, but usually when someone uses the acronym “DTF” they are typically referring to the commonly found ink-based DTF systems that require color and white ink printing on a clear film and then baking TPU powder over the wet print.

This is clever marketing but not wrong either! What we can say without exception is that the latest White Toner Transfer Printers are truly the best DTF alternative and are most suitable for beginners who are trying to grow their business from scratch.

But what is a White Toner Transfer Printer? Simply put, these are laser or LED printers that are retrofitted with white toner. In most cases the white toner replaces the black toner in the printer, so you are printing with cyan, magenta, yellow, and white. The black colors are created instead of what's known as "composite" black, which is essentially a combination of the CMY toners combined. Note the use of the word TONER! We do not use any liquid ink in these machines; instead, we use dry toner, which is a dry powder that is essentially made of milled and refined colored plastic.

The Advantages Being:

- • No Maintenance

- • No Expiration Dates

- • No Clogging, ever!

- • Significantly faster printing times vs. ink-based systems

- • More printing versatility

- • Significantly longer hardware durability vs. ink-based printers

Overall, these machines are relatively trouble-free as compared to ink delivery systems (sublimation, DTG, DTF, etc).

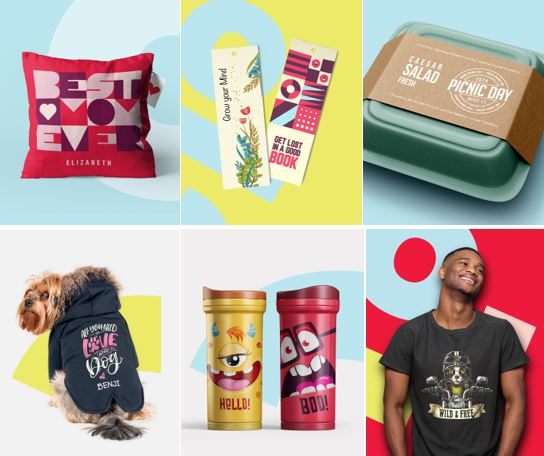

Now that we know what it is, What Do We Use a White Toner Transfer Printer For? Well, for the most part, most users create heat transfers for use on garments with their machines. This technology fits into the "short run" solution for most users, allowing you to produce smaller quantities that most screen printers would pass over. Textile printing is the #1 use for a white toner printer. The advantage is that you can print 1 or 100 transfers and apply them onto ANY fabric color and any fabric type! So, while all other garment decorating techniques have some limitation of material and/or color, we have none of those restrictions with white toner printing.

Additionally, there are MANY other unique applications like wood, acrylic, glass, ceramic, metal, leather, paper, window clings, labels, cardstock, magnetic paper, tattoos, candle printing, etc., etc... the list goes on and on. A White toner transfer printer is simply the most flexible addition you can make to your business because you are not limited to just one application. It does SO much and fits in a small space in your shop, and many machines are even portable so you can throw them in a trunk and take them on the road with you. If you had to pick just one machine to start your business with, this is it!

Sounds Great, What's the Catch?

Well, no real CATCH, but the common things that come up after purchase that cause pain for beginners are the following:

1. You need a high-quality heat press, unlike sublimation and vinyl, which do fine with low-quality presses. Consistent heat and pressure are VITAL to a successful transfer.

2. Solid areas will benefit from "rasterization," which is a technique that lets us add open areas, or "negative space," to your graphic to let the garment breathe and stretch to prevent cracking. This look might be objected to, especially when you are first starting out and don't know all the advanced techniques used to improve the look (called variable rasterization).

3. While you can print transfers VERY VERY fast (10-20 per minute!), it takes around 2-3 minutes per transfer to make a shirt. This can be improved with multiple presses and people, of course.

4. Transfer printers require transfer paper! While many new users get hung up on the consumable cost of toner, the real cost is the transfer paper and TIME. Transfer paper averages around $1.50 to $2 per A4/letter-sized sheet and double that for the larger A3/tabloid-sized papers. So, if you add the cost of a t-shirt plus paper, you are in the $4 cost range plus labor.

5. You need decent graphics skills. Photoshop, Illustrator, Corel Draw, Affinity, etc. You want to have a good understanding of file types, transparency, etc., as you jump into white toner printing.

6. White toner transfer printers work with PCs only unless you use emulation software on your Mac.